Plasma Arc Fume Extractor

Product Description

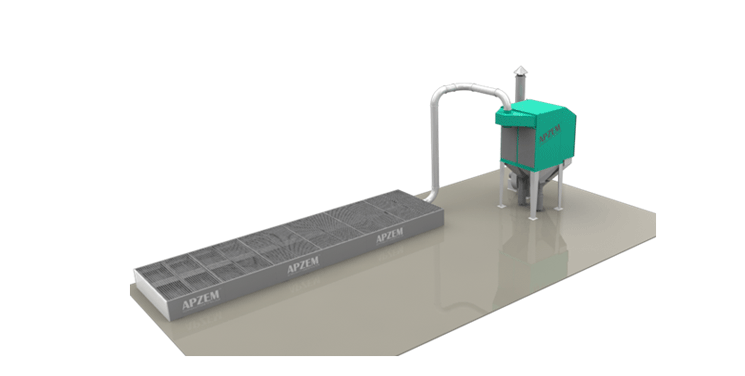

Apzem Plasma arc Fume Extractor are designed specifically for CNC Plasma cutting table capture hazardous fumes and dusts generated during plasma cutting. All our plasma cutting fume extractor is dry and down drafted and modular in design. Plasma Cutting allows cutting of metals that could not be flame cut, such as stainless steel, aluminum and copper. Plasma cutting uses electrically conductive gas to transfer energy through the plasma torch to the material being cut.

Plasma gases include argon, hydrogen, nitrogen and mixtures, plus air and oxygen.Welding often generates gases and smoke containing particles of various types of oxides. The size of the particles can influence the toxicity of the fumes, with smaller particles presenting a greater danger. Additionally, many processes produce gases (most commonly carbon dioxide and ozone, but others as well) that can prove dangerous if ventilation is inadequate.The generation rate of fumes and gases varies with the composition of the base metal, fluxes, and fillers, and with the rate and depth of welding or cutting. Exposure to the operator varies with the generation rate, duration and frequency of operations, work practices and the effectiveness of ventilation.

Unlike welding, where the main risk is rising smoke and fumes that need to be captured before they reach the welder’s breathing zone, cutting creates another problem: Due to the high cutting pressure during plasma, dust, sparks and fumes are pushed into the table and get swirled up again to the top. A conventional extraction from the bottom or the sides would not be sufficient, and employees and machinery alike would suffer from various health problems or break downs.

Apzem extraction table which takes advantage of the rising dust, by creating a cyclone like air flow where sparks and heavy particles get separated on the bottom, and fumes and finer particles are captured near the surface of the table. The table segments come in various widths and can be joined together to achieve any desired cutting bed size (and can be even added on later) according to your budget and size requirements.An oscillating conveyor continuously moves slag and debris generated during the cutting process into a container positioned at the end of the table.The result is a more efficient utilization of the cutting station and therefore improved efficiency of the cutting plant.

Advantage:

Continuous discharge

Higher efficiency of cutting station

Dust elimination

Extended wear-and-tear through separation of mechanical parts

Minimal down times

Minimal maintenance

Plasma cutting utilizes a high velocity plasma gas jet formed by an arc and inert gas flow to create extremely high temperatures which melts the targeted material and forces the molten metal through the back side of the cut. Laser cutting utilizes a high intensity light beam to melt or vaporize materials and may incorporate a gas jet, which blows away the molten metal.

Apzem fume extractor can be custom configured to your existing CNC table or we also supply our system along with CNC plasma cutting Bed based on your needs. For enquiries or to know more feel free to contact us @ 9789066648 / 044-42879231 or email to sales@apzem.com

Higher efficiency of cutting station

Dust elimination

Extended wear-and-tear through separation of mechanical parts

Minimal down times

Minimal maintenance

Plasma cutting utilizes a high velocity plasma gas jet formed by an arc and inert gas flow to create extremely high temperatures which melts the targeted material and forces the molten metal through the back side of the cut. Laser cutting utilizes a high intensity light beam to melt or vaporize materials and may incorporate a gas jet, which blows away the molten metal.

Apzem fume extractor can be custom configured to your existing CNC table or we also supply our system along with CNC plasma cutting Bed based on your needs. For enquiries or to know more feel free to contact us @ 9789066648 / 044-42879231 or email to sales@apzem.com

Technical Specification

- MODEL NO: PFE-5000

- OVERALL DIMENSION: 980*430*430mm

- CABINET CONSTRUCTION: Brushed stainless steel/Powder Coated Mild Steel

- SUCTION CAPACITY: 100CFM

- FILTERATION: 3 Stages

- PRE FILTER: 95%@ 0.8 microns

- HEAP FILTER 99.99% @ 0.3 microns

- ABSORBENT MEDIA FILTER: To Remove Odour's

- ELECTRICAL: 100-240v 1ph 50/60hz

- WARRANTY: 1yr

Other Technical Details

Accessories

Certification

Warranty

Accessories

Blower, filters, pre filter, fine filter, Heap filter, Ducts, flexible duct, Hood, Flexible arm, Carbon filter, spiral Duct, frp duct, ms duct, slide gates

Certification

All Apzem Products are designed to comply with ACGIH and OSHA standards as well as local PCB Standards.

Warranty

All Apzem Products are minimum one year waranted for performance and quality.